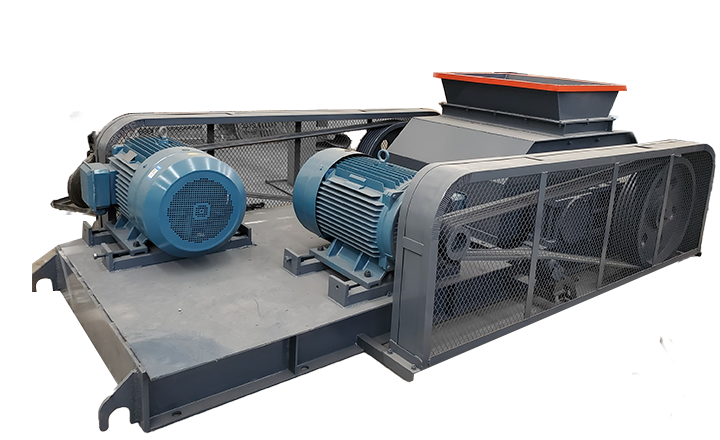

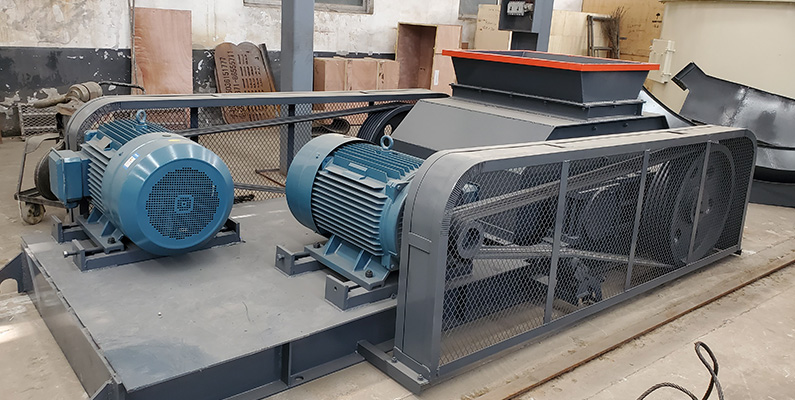

Double Roller Crusher advantage

-

01Simple structure ,easy to operation and maintenance.

-

02The interior is equipped with dustproof plates, good sealing performance, avoiding the splash of fine materials after crushing, low working noise.

-

03The grinding roller is equipped with a replaceable wear-resistant liner, which has the characteristics of long service life, not easy to damage, and convenient maintenance.

-

04The machine is equipped with a safety protection device, when there is a metal iron into the crushing chamber, the protective device action, iron leakage equipment normal operation.