Single Cylinder Hydraulic Cone Crusher advantages

-

01Due to adopting hydraulic adjustment system of discharge , it can be adjusted timely and enable full-load operation to improving the lifetime of wear parts and reduce the operation cost.

-

02With the same internal structure , it can get the different crushing chamber though replacing the liner to meet the different crushing requirement and save the cost for clients.

-

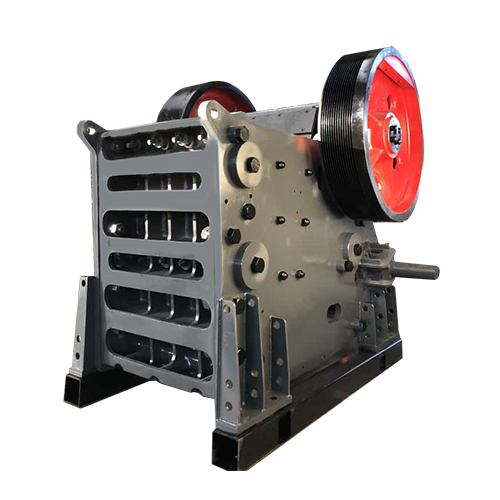

03With large feeding design, DP series cone crusher can provide good combination with primary jaw crusher and improves the crushing capacity.

-

04Adopting advanced hydraulic technology, overload protection can be realized effectively ,which simplify the structure of crusher and make the operation and maintenance to be more easier and convenient.