How to choose a high-quality jaw crusher

Oct 20, 2023

Industry news

If you are looking for related products or have any other questions, you can call our company's sales hotline at any time!

Phone/whatsapp:

A jaw crusher is widely recognized for its simple structure, high crushing ratio, reliable performance, and low operating cost. However, with numerous manufacturers producing jaw crushers worldwide, it is crucial to understand the production process to identify a superior product. As a professional crusher manufacturer, FLAMCO Crusher provides detailed insights into the production process of our high-quality jaw crushers.

A jaw crusher is widely recognized for its simple structure, high crushing ratio, reliable performance, and low operating cost. However, with numerous manufacturers producing jaw crushers worldwide, it is crucial to understand the production process to identify a superior product. As a professional crusher manufacturer, FLAMCO Crusher provides detailed insights into the production process of our high-quality jaw crushers.

1. Raw Materials:

FLAMCO Crusher collaborates with prominent Chinese steel plate factories, including An-Steel and Bao-steel, to ensure the use of top-grade steel plates, guaranteeing the highest quality. Additionally, we have a sister casting factory that produces high-quality casting parts such as swing jaws and jaw plates. FLAMCO also incorporates renowned Chinese bearing brands like ZWZ, LYC, and HRB to ensure reliable performance.

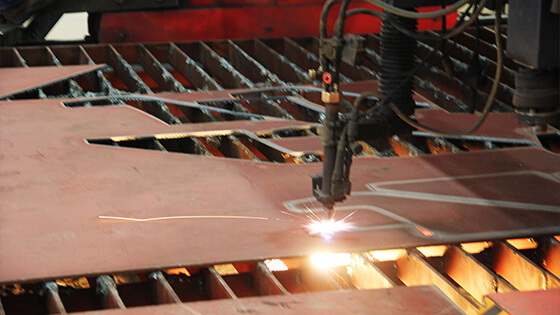

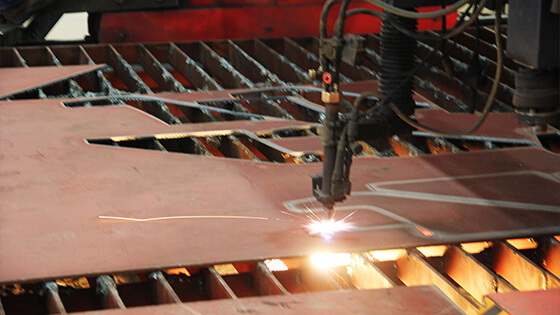

2. Cutting Process of Steel Plates:

FLAMCO Crusher employs advanced CNC plasma cutting machines in our state-of-the-art workshop to cut steel plates of varying thicknesses. This process ensures precise cutting and reduces deviations, maintaining accuracy throughout the manufacturing process.

3. Fine Finishing Processing of Parts:

FLAMCO Crusher utilizes cutting-edge machinery, including CNC floor milling and boring machines, CNC double column vertical lathes, CNC horizontal heavy lathes, and radial drilling machines. Our experienced and skilled engineering team ensures precise control over critical parts such as swing jaws and main shafts. This meticulous approach ensures that FLAMCO jaw crushers are in optimal condition, prolonging their lifespan and enhancing overall performance.

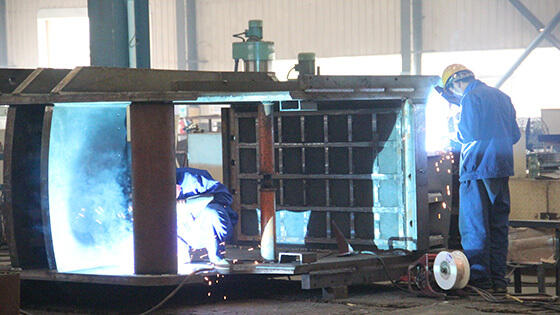

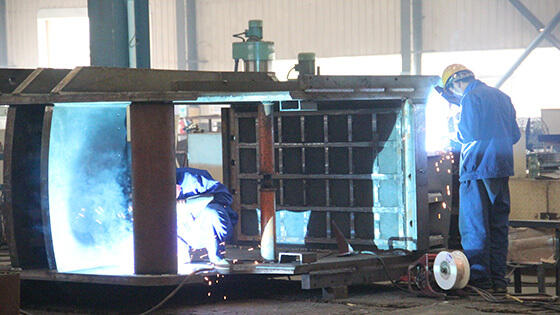

4. Assembly and Welding Process:

FLAMCO has a team of highly experienced and skilled engineers, many of whom have served the company for over 10 years. This dedicated team meticulously assembles all the parts in the correct positions and ensures strong welds, resulting in well-functioning and durable FLAMCO jaw crushers.

5. Painting Process:

FLAMCO jaw crushers undergo a comprehensive painting process to enhance their appearance and protect against corrosion. This process includes sand blasting, primer painting, putty finishing, and topcoat painting, ensuring a visually appealing and long-lasting finish.

6. Testing:

To ensure optimal performance and minimize quality defects, all FLAMCO crushers undergo a rigorous 24-hour testing period. This thorough testing guarantees that customers receive reliable and high-performing equipment.

While maintaining superior quality, FLAMCO Crusher adopts batch production whenever possible to reduce production costs.

FLAMCO not only produces a full range of crushing, grinding, screening, and conveying equipment but also provides top-notch after-sales service in both domestic and overseas markets. Our dedication to customer satisfaction is evident in constant commitment to delivering high-quality products and comprehensive support.

1. Raw Materials:

FLAMCO Crusher collaborates with prominent Chinese steel plate factories, including An-Steel and Bao-steel, to ensure the use of top-grade steel plates, guaranteeing the highest quality. Additionally, we have a sister casting factory that produces high-quality casting parts such as swing jaws and jaw plates. FLAMCO also incorporates renowned Chinese bearing brands like ZWZ, LYC, and HRB to ensure reliable performance.

2. Cutting Process of Steel Plates:

FLAMCO Crusher employs advanced CNC plasma cutting machines in our state-of-the-art workshop to cut steel plates of varying thicknesses. This process ensures precise cutting and reduces deviations, maintaining accuracy throughout the manufacturing process.

3. Fine Finishing Processing of Parts:

FLAMCO Crusher utilizes cutting-edge machinery, including CNC floor milling and boring machines, CNC double column vertical lathes, CNC horizontal heavy lathes, and radial drilling machines. Our experienced and skilled engineering team ensures precise control over critical parts such as swing jaws and main shafts. This meticulous approach ensures that FLAMCO jaw crushers are in optimal condition, prolonging their lifespan and enhancing overall performance.

4. Assembly and Welding Process:

FLAMCO has a team of highly experienced and skilled engineers, many of whom have served the company for over 10 years. This dedicated team meticulously assembles all the parts in the correct positions and ensures strong welds, resulting in well-functioning and durable FLAMCO jaw crushers.

5. Painting Process:

FLAMCO jaw crushers undergo a comprehensive painting process to enhance their appearance and protect against corrosion. This process includes sand blasting, primer painting, putty finishing, and topcoat painting, ensuring a visually appealing and long-lasting finish.

6. Testing:

To ensure optimal performance and minimize quality defects, all FLAMCO crushers undergo a rigorous 24-hour testing period. This thorough testing guarantees that customers receive reliable and high-performing equipment.

While maintaining superior quality, FLAMCO Crusher adopts batch production whenever possible to reduce production costs.

FLAMCO not only produces a full range of crushing, grinding, screening, and conveying equipment but also provides top-notch after-sales service in both domestic and overseas markets. Our dedication to customer satisfaction is evident in constant commitment to delivering high-quality products and comprehensive support.

If you have any questions about "Crushing and screening equipment"?

Welcome to call Zhengzhou FLAMCO Industrial Co., Ltd. toll-free number: +86 13213078528

or click to order the equipment introduced in the article.

Welcome to call Zhengzhou FLAMCO Industrial Co., Ltd. toll-free number: +86 13213078528

or click to order the equipment introduced in the article.

Previous:

Back to list

Next:

Back to list